Responding to increased demand for robotic production in industrial worksites in developed countries and emerging nations

Free communication driver and dedicated HMI screens for use with Yaskawa robot controllers

Brief

Osaka, Japan - July 10, 2012 - Pro-face, the global leader of Human Machine Interface (HMI) and factory data communication solutions, announces the worldwide release of a free communication driver and dedicated screens for Yaskawa Electric DX100/FS100 robot controllers. The new products have been produced in response to increased demand for robotic production in industrial worksites in developed countries and emerging nations, and will be available for download free of charge from the Pro-face website from August 3, 2012.

The dedicated driver for robot controller communication and dedicated screens were developed to meet the requirements of a variety of key industries including the automotive, semiconductor, liquid crystal, photovoltaic cell, LED, and electronic component sectors. These requirements include the need to improve quality and expand productivity in developed countries; the increasing need to automate production due to soaring labor costs and labor shortages in emerging nations; and the need for visualization to enable the prompt resolution of problems on worksites where robot systems have been introduced.

Unlike conventional systems that require specific qualified personnel to use a programming pendant to check robot status, the new driver makes it possible to check the same information using an HMI (touch panel). A touch panel provides unified management by enabling on-screen confirmation of the status of the entire robot system including the robot itself, and control equipment such as PLCs and sensors. This helps to lessen downtime by reducing the hassle associated with checking a variety of devices to ascertain the cause in the event that the robot performs an emergency stop. Moreover, the dedicated screens can be integrated into existing screen data using Pro-face's screen editing and logic program software (GP-Pro EX) so there is no need to create new programs or screens from scratch.

Based on its corporate slogan, ”Pro-face for the best interface”, Pro-face aims to develop products that act as the best interface and can be connected to a variety of control equipment on the production worksite.

|

|

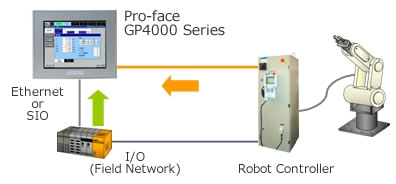

| Connection diagram of programmable display and robot controller |

Features

- Supports simultaneous communication between control equipment and robot controller for unified robot system management.

- Allows robot axis operation without a programming pendant.

- Check robot status and detailed explanations regarding robot controller alarms and alarm history.

- Maintenance tasks like robot controller greasing and battery replacement periods can be controlled from a touch panel.

- Job programs can be backed up from the robot controller to the HMI.

Availability

* Requires separate screen editing and logic program software (GP-Pro EX).

* User registration required in order to download.

Inquiry

If you have any inquiries, please contact our sales office in your region.

For contact information, please refer to the "Inquiry" page.